DEPOSITOR

F O C U S

DEPOSITOR:

EXPERTISE

IN PASTRY DOSING

The DEM depositor is the result of IBL experience in the dosing pastry through the most modern technology.

Designed for industrial use and to offer the maximum versatility, the IBL depositor is the ideal machine for depositing or extruding in continuous or with wire cut, swirl, diaphragm on dedicated belt or on oven steel band steel band a wide range of doughs, from fluids to viscous ones, also with nuts, chocolate, candies and so on.

The IBL depositor can work, preserving the consistency and structure of the dough at a speed of 50-80 cycles/min. with vertical and horizontal movements and up to 100 cycles/min. in wire cutting, for an endless range of products. The various interchangeable accessories for extrusion or co-extrusion, and such as with wire-cut swirl diaphragm guillotine allow an endless range of products.

Each dosing phase is are managed by the innovative IBL colors HMI (touch screen), connected to the machines with wifi control or fixed on the machine. Through the HMI, you can control the depositor movements to better manage the shape of the cookie and the desired production and saving the recipes.

INNOVATIVE TOUCH SCREEN:

BETTER MANAGEMENT

OF PRODUCTION

Each dosing phase is are managed by the innovative IBL colors HMI (touch screen), connected to the machines with wifi control or fixed on the machine. Through the HMI, you can control the depositor movements to better manage the shape of the cookie and the desired production and saving the recipes.

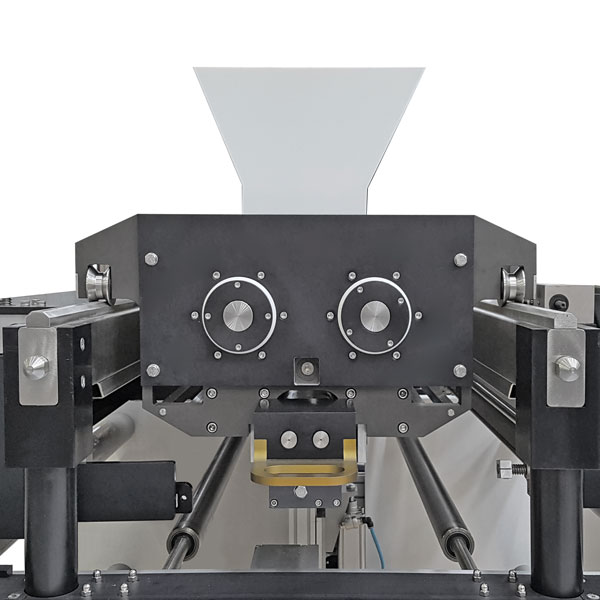

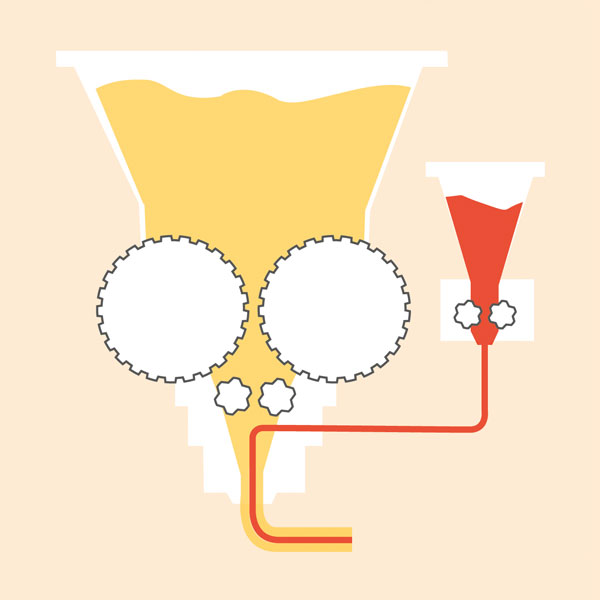

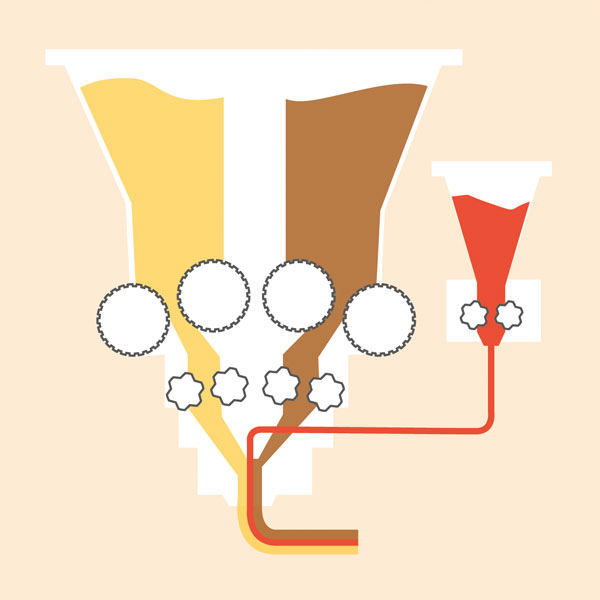

THE HEADER:

DOSE YOUR DOUGH WITH PRECISION

Depositor’s heart, the header, is available in mono-color and bicolor versions. It is made of one or two couples of motorized rollers that feed the underlying volumetric pumps, able to dose the dough with precision across the working width.

Through an additional head, the Jelly Topper, it is possible to integrate the product with creams or jams topping.

Single color depositor

Double color depositor

NOZZLES:

INFINITE PRODUCTS

WHERE TO CHOOSE

Made of bronze or plastic material, the interchangeable nozzles offer the possibility of producing an infinite number of different products.

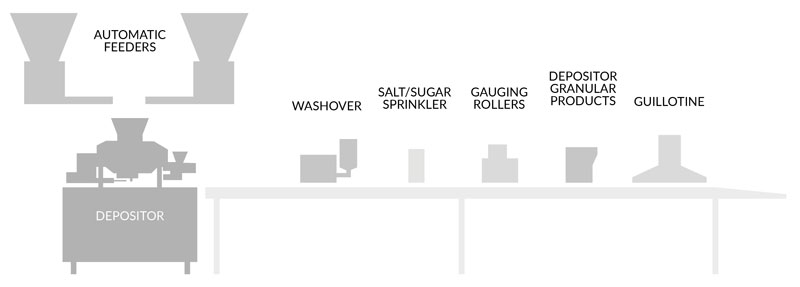

AND NOW…

COMPLETE YOUR DROPPED LINE!

A LOT OF GOOD REASONS