SNACK CAKES LINE

Sponge cake is a base widely used in the pastry- making industry to make many kinds of snacks. The main ingredients are: flour, eggs and sugar. For its soft and spongy texture but also for its nutritional value and ability to gratify the palate, sponge cake is also perfect to make a wide variety of packaged snacks. The industrial line dedicated to the production of sponge cake snacks, consists of the preparation of dough with the use of a mixer machine suitable for the pre-mixing of the ingredients. At the end of this first phase the dough is transferred by means of a pumping system, in a tank of adequate capacity to the production, which provides an uninterrupted power supply of the turbo-emulsier for the completion of the dough, which must be evenly aerated and with the required volume at the end of the cycle.

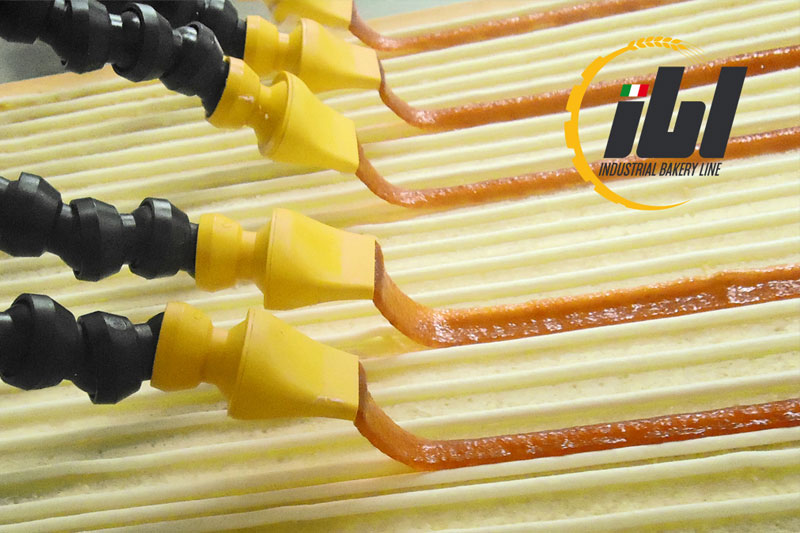

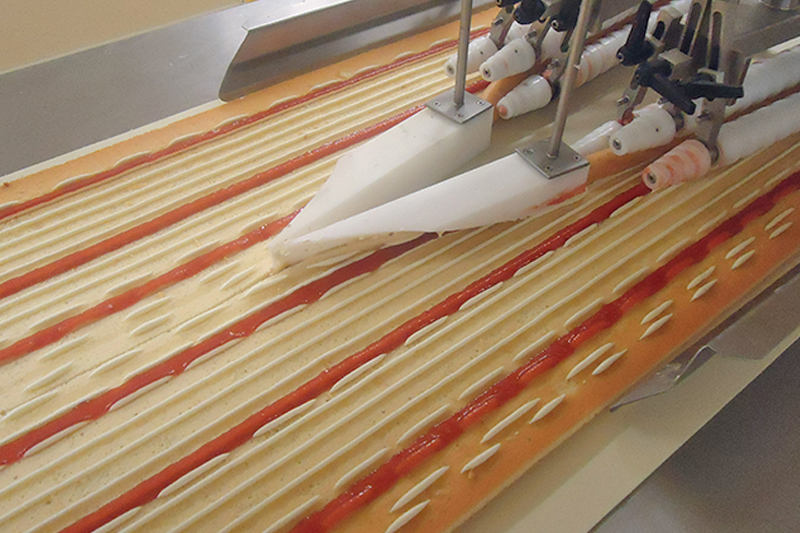

A suitable pumping system then provides the subsequent transfer of the dough into the hopper of the extrusion head, positioned directly on the oven. The oven, direct gas in the first part and the second radiant cyclothermic, then take steps to ensure a perfectly baking. The automatic work table provides then the processing, wetting, filling (with cream, chocolate, jam), and molding by dedicated accessories. The enrobing and decoration sections allow it in chocolate decorations. The production line is also here customizable in function of the production layout width that can vary from 600 mm up to 1200 mm

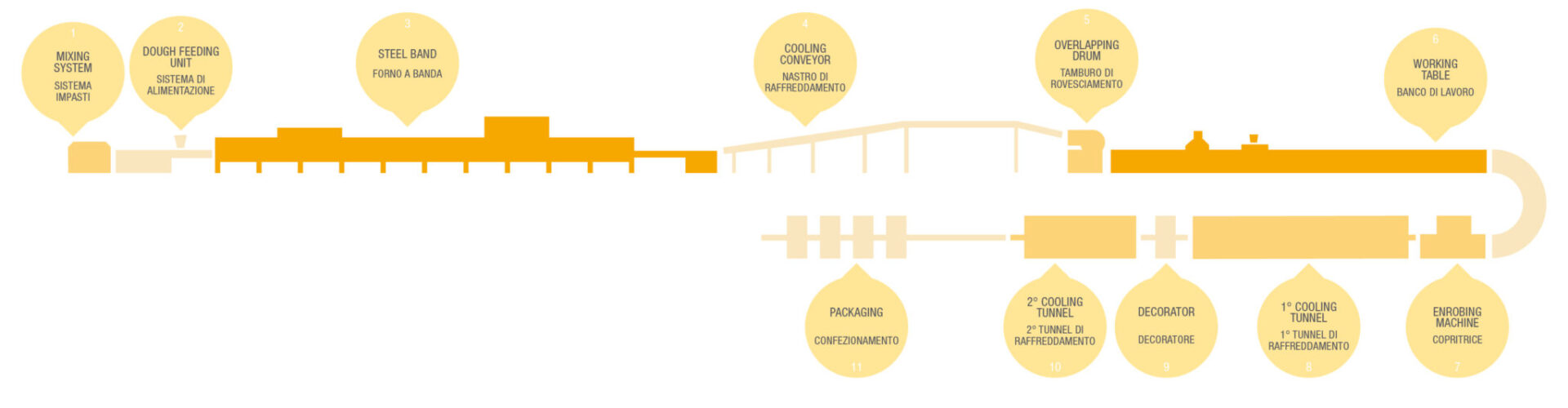

EXAMPLE OF

SNACK CAKES LINE

MIXING SYSTEM

DOUGH FEEDING UNIT

COOLING CONVEYOR

WORKING TABLE

ENROBING MACHINE

1° COOLING TUNNEL

DECORATOR

2° COOLING TUNNEL

PACKAGING

1. MIXING SYSTEM

Designed to form mixtures from crackers, hard biscuits, shortbread biscuits, extruded products and other types of leavened products, it is built in various models with capacities from 200 to 1100 litres.

2. DOUGH FEEDING UNIT

The star feeder receives the dough from the mixer and cuts the dough in pieces for the smooth feeding of the sheeter. The feeder is composed of a stainless steel hopper of about 350 liters lined with anti-sticking plastic and of a bottom star cutter with a sloped conveyor.

3. STEEL BAND OVEN

The oven, direct gas in the first part and the second radiant cyclothermic, then take steps to ensure a perfectly baking.

4. COOLING CONVEYOR

Modular structure for easy assembling. Structure is in stainless steel. Foodgrade plastic belt FDA approved.

5. OVERLAPPING DRUM

The overlapping drum flips the sponge dough before being processed on the working table.

6. WORKING TABLE

Conveyor belt of process for the Sponge cake’s working. It is equipped with a structure of lateral support useful to lodge the different working stations, according to the product to manufacture.

7. ENROBING MACHINE

Machine for total or partial coating of chocolate on sponge cake products. It is inserted at the end of the line together with a cooling tunnel. Equipped with a heated tub with chocolate recovery and recycling system. Control panel on the machine.

8. FIRST COOLING TUNNEL

Tunnel is covered by insulated panels. Covering is mounted on gas cylinders to facilitate opening/closing for necessary maintenance and cleaning operation. Containing group of the evaporators and ventilators positioned inside the tunnel structure. Temperature control inside, with regulation.

9. DECORATOR

Bearing structure made of stainless steel AISI 304. Wire-mesh conveyor, manually removable covering for cleaning operation. Equipped with motorization driven by frequency converter. Zigzag finisher, controlled by gearmotor and frequency converter controlling the oscillations.

10. SECOND COOLING TUNNEL

Tunnel is covered by insulated panels. Covering is mounted on gas cylinders to facilitate opening/closing for necessary maintenance and cleaning operation. Containing group of the evaporators and ventilators positioned inside the tunnel structure. Temperature control inside, with regulation.

11. PACKAGING

The horizontal packaging machine is the most requested machine for sponge cake products. Speed up to 250 beats per minute. Packaging for single product. Electronically regulated speed. Automatic reel change.