TUNNEL OVEN

AT each baking its TUNNEL oven

Cooking is the most important phase of the whole production process of any bakery product. In addition to a suitable tunnel oven, each product requires specific customizations.

This is why IBL pays special attention and care in the construction of its tunnel ovens.

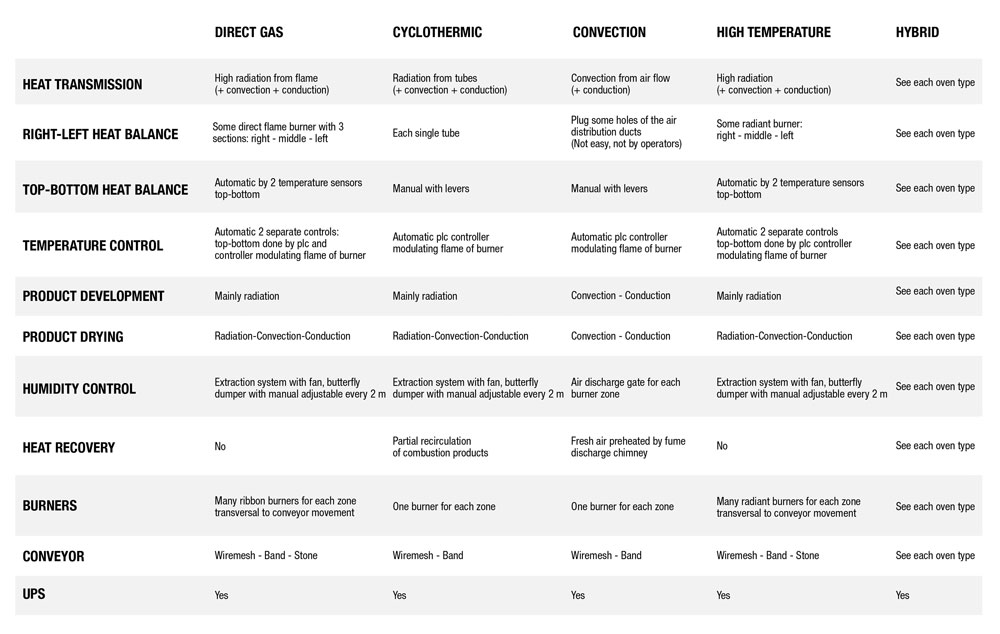

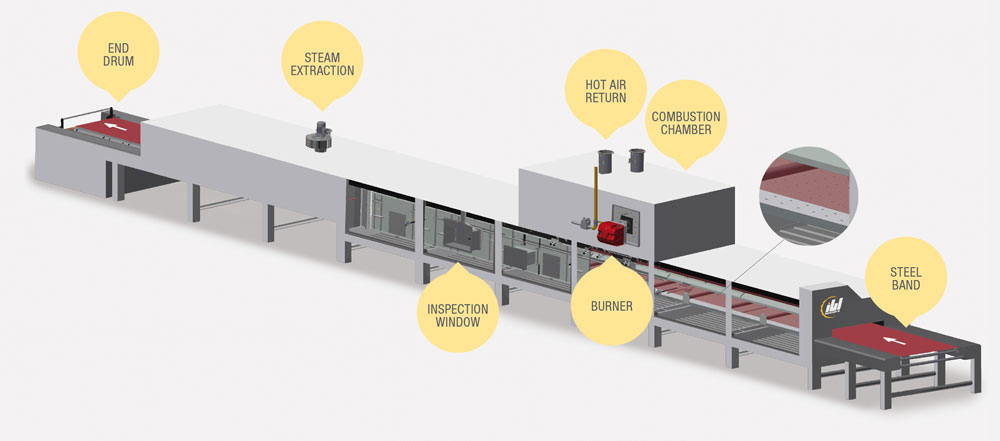

CONVECTION

Suitable for artisanal or small/medium-sized laboratories with particular flexibility required during the production day

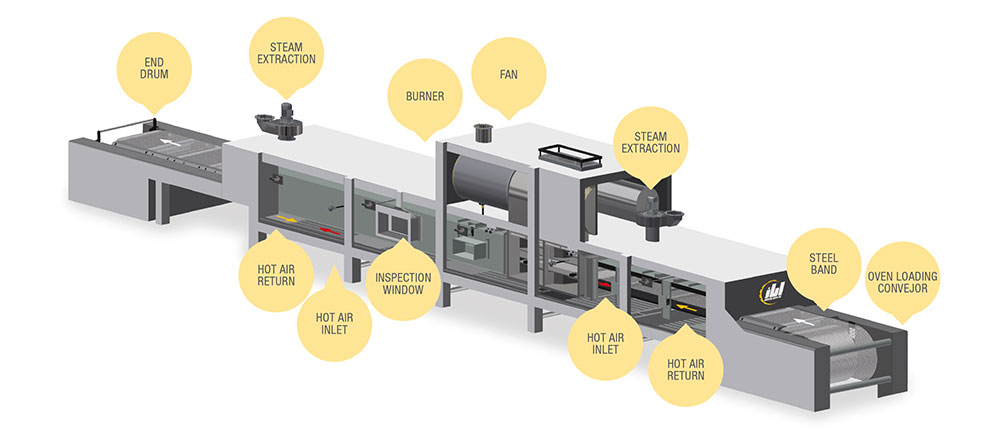

CYCLOTHERMIC

Particularly suitable for large laboratories, they allow a variety of products to be baked, from biscuits to medium or large-sized bread

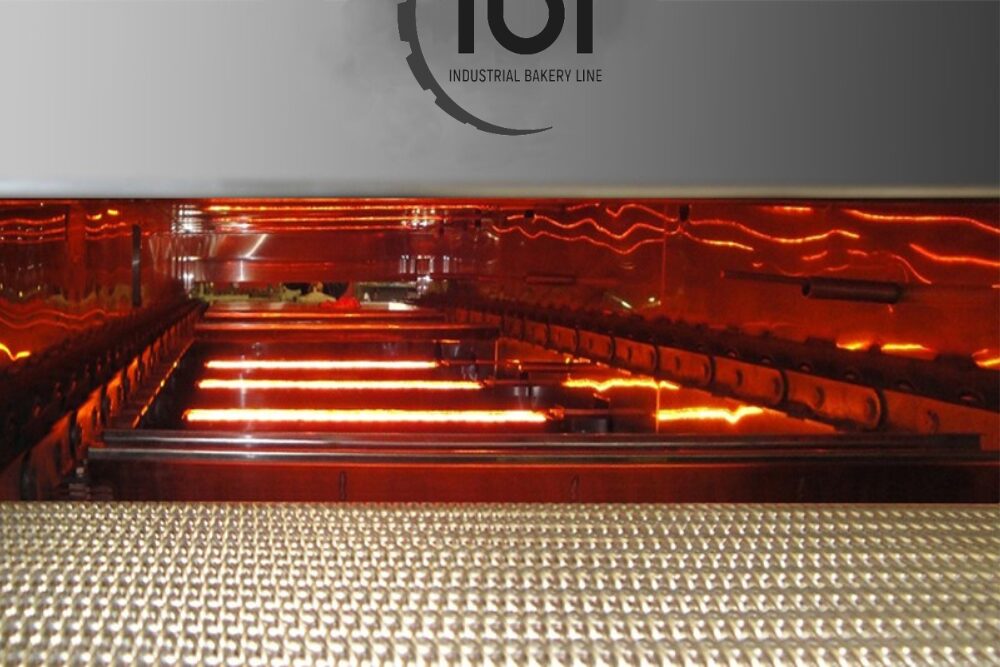

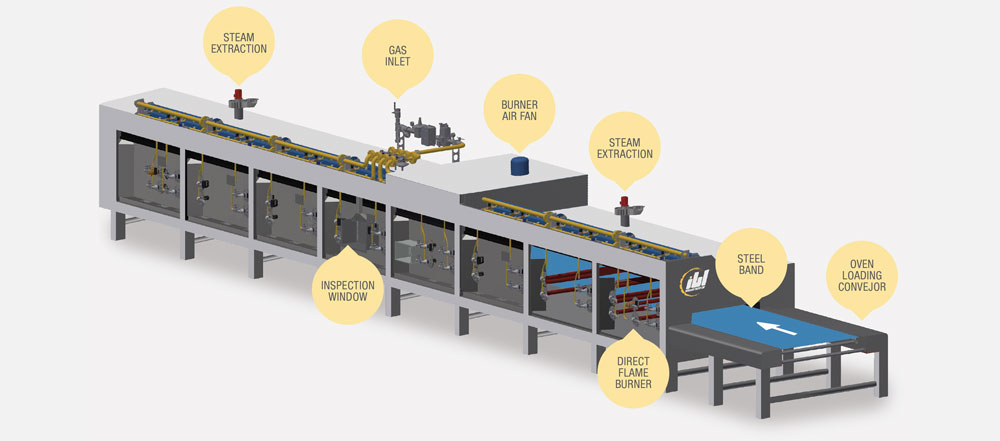

DIRECT GAS

Ideal for laminated and roto-moulded biscuits such as snack cakes, crackers, petit beur etc, which require high temperatures and short cooking times

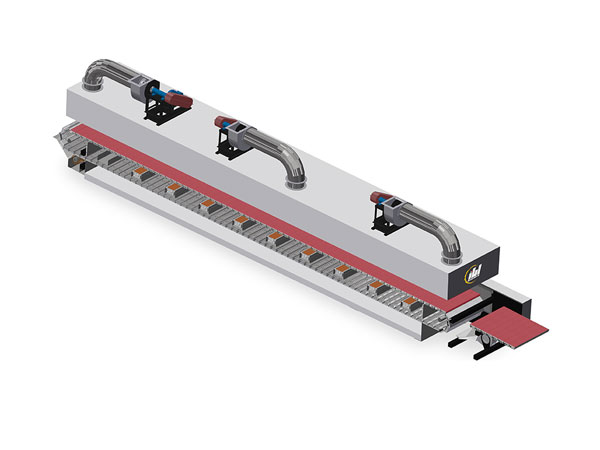

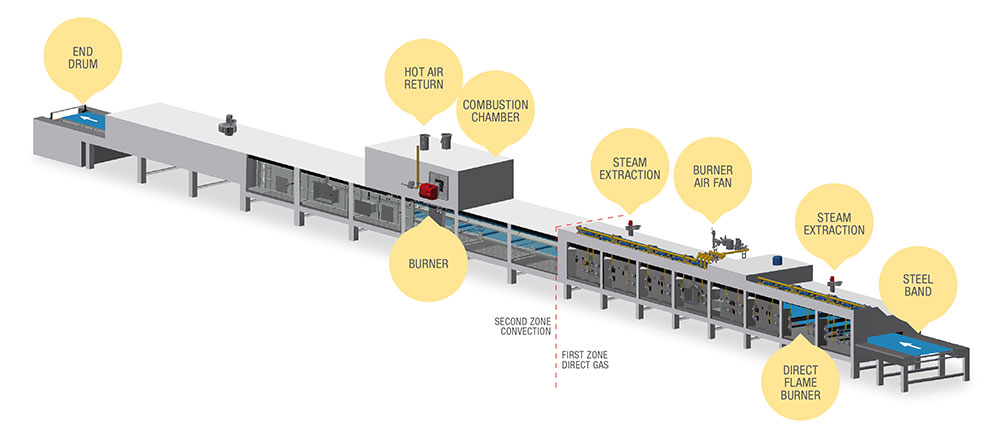

HYBRID

The hybrid tunnel oven baking system is used by combining two or more different heating systems

HIGH TEMPERATURE

Suitable for products requiring high temperatures (400°C) and reduced cooking times (120 sec)

STORYTELLING

HOW CRACKERS ARE BORN

It is a pleasure for us to tell you directly from within our Company the steps that lead to the realization of our products, from the smallest lamination machine, through the production of ovens, up to complete automatic production lines.

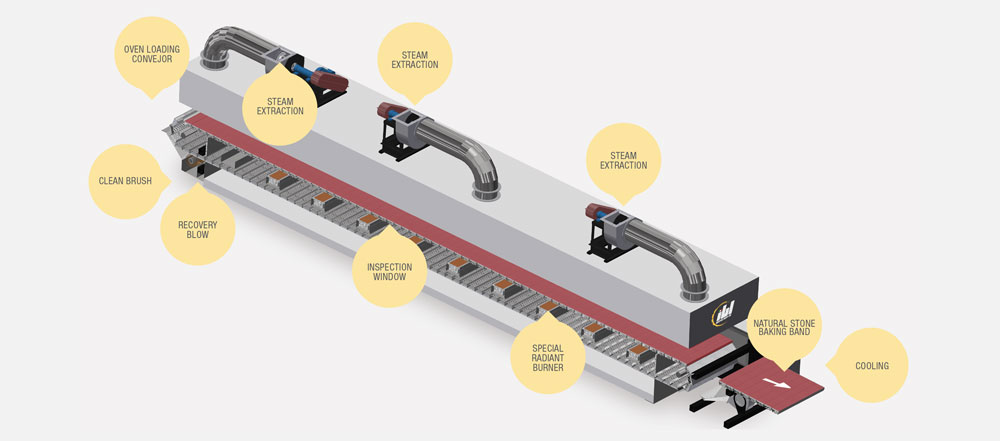

Today we want to show you some frames of the production of a hybrid oven, the heart of the production of mini crackers, consisting of a first part with direct gas and a second part with convection.

CONVECTION

Indirect forced air convection oven is suitable for baking of products ranging from soft dough products through hard/sweet to enzyme type cracker and combined with sections of the multi-burner system to form a hybrid solution for snack type products.

Oven consist of assembled modular structure supported by steel frame fixed to the floor.

As a consequence of the heating, the baking chambers have the possibility to dilate, thanks to a specially designed sliding system.

Chambers and the combustion groups are constructed from materials suitable for operation at high temperatures.

Thermal insulation of rock wool or ceramic fibers is enclosed by protection panels and stainless steel covers.

Convection oven indirectly applies the temperature, obtained into the combustion chamber via a burner and via a stainless steel fan for air circulation. This heat is separated by a shutter into top and bottom pressure chambers. Each one of the pressure chambers can be independently controlled to maximize the energy efficient application to the product.

Presence of a heat exchanger coupled with the re-circulation of air from the baking chamber via the combustion chamber, allows rapid response to temperature fluctuations.

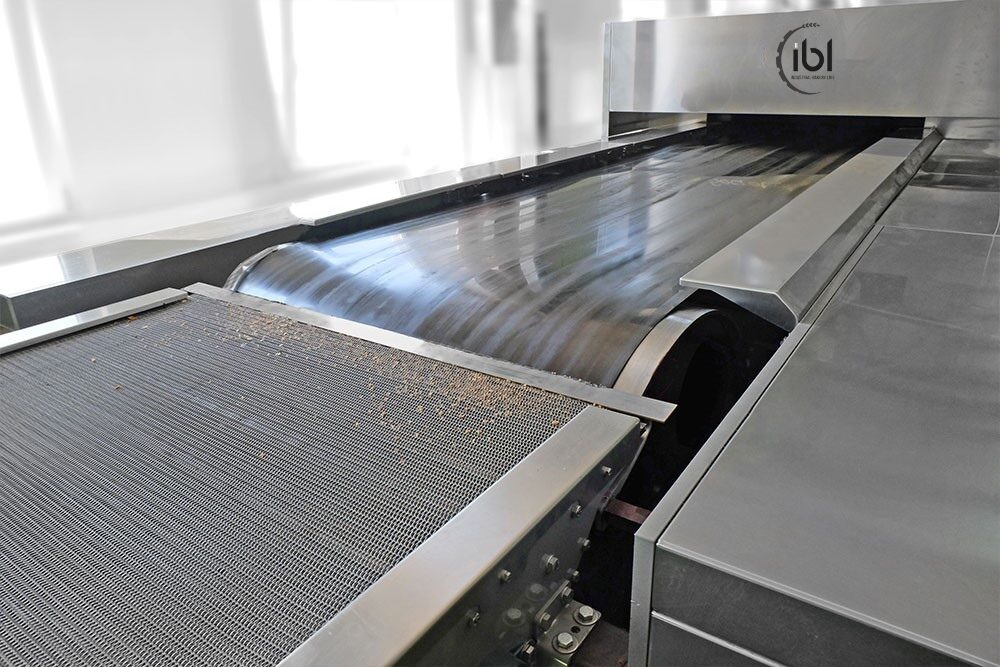

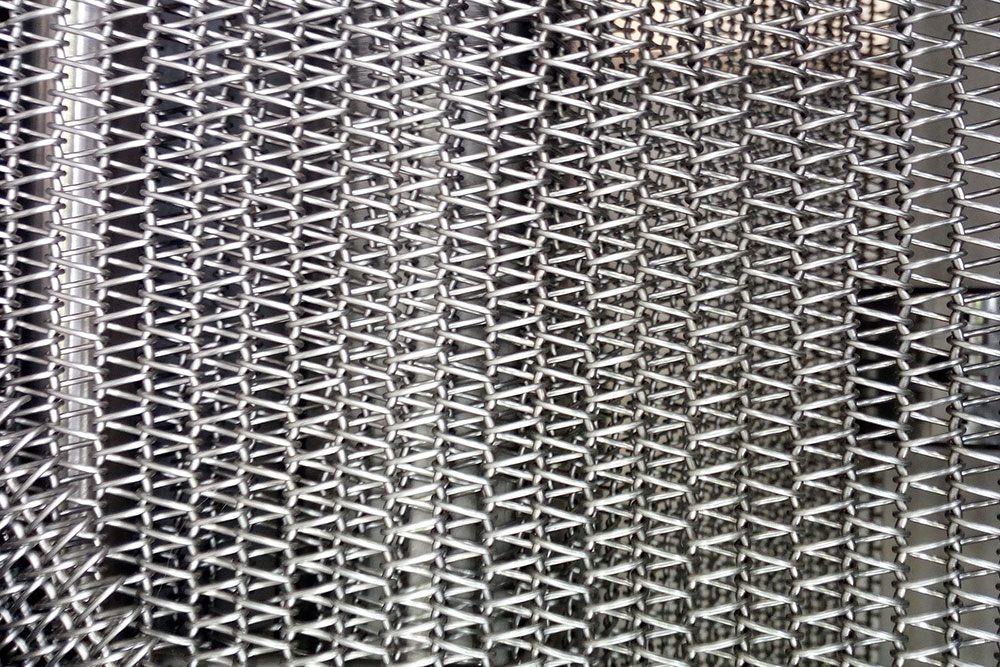

Idle head includes a system of pneumatic tensioning.

Towing group, positioned on the output head, is composed of a motor controlled by inverter and a towing device that can be manually activated in case of emergency.

Whole system is controlled by an electrical panel placed near the oven.

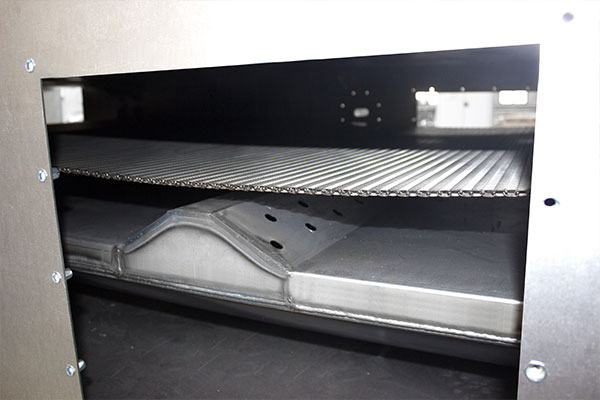

CYCLOTHERMIC

Cyclotherm oven is suitable for baking of products ranging from cupcake, Swiss roll and other sponge products, extruded, wire cut and rotary moulded soft dough products through to hard/sweet and bread. Oven consist of assembled modular structure supported by steel frame fixed to the floor. As a consequence of the heating, the baking chambers have the possibility to dilate, thanks to a specially designed “sliding” system. Chambers and the combustion groups are constructed from materials suitable for operation at high temperatures. Thermal insulation of rock wool or ceramic fibers is enclosed by protection panels and stainless steel covers.Oven baking chamber is constructed to include segregated channels through which the heat from the power module is transferred to the radiators placed above and below the oven conveyor.

A sufficient number of channels is provided to supply a balanced thermal load. Cyclotherm oven applies the temperature, obtained into the combustion chamber via a stainless steel burner and via a re-circulation fan to the top and bottom radiators (sheaf of tubes). Heat transfer to the two radiators is independently controlled. Idle head includes a system of pneumatic tensioning.

Towing group, positioned on the output head, is composed of a motor controlled by inverter and a towing device that can be manually activated in case of emergency.

Whole system is controlled by an electrical panel placed near the oven.

DIRECT GAS

Direct gas fired oven is suitable for baking of products ranging from soft dough products through hard/sweet to cracker, soda cracker and baked (not fried) snack type products. The combination with cyclotherm or convection sections can be used as hybrid solutions for baked snack type products.

Oven consist of assembled modular structure supported by steel frame fixed to the floor. As a consequence of the heating, the baking chambers have the possibility to dilate, thanks to a specially designed sliding system.

Chambers and the combustion groups are constructed from materials suitable for operation at high temperatures.

Thermal insulation of rock wool or ceramic fibers is enclosed by protection panels and stainless steel covers.

Heat transmission inside the oven is achieved thanks to the combustion generated by the burners positioned on the top and the bottom of the baking chamber.

Multi-burner gas oven is supplied with combined system with controlled ignition, self-checking spark and flame, burner safety system to each single burner, conforming with worldwide safety regulations.

Idle head includes a system of pneumatic tensioning. Towing group, positioned on the output head, is composed of a motor controlled by inverter and a towing device that can be manually activated in case of emergency. Whole system is controlled by an electrical panel placed near the oven.

HYBRID

The Hybrid Oven system is used to match two or more different heating systems.

The baking flexibility is highlighted in the thermal settings, with the possibility of differentiating the temperature of each zone, by moving air inside the baking chamber and managing the vapor suction system in each individual zone.

The following combinations of oven can be obtained:

– Direct flame + cyclothermal

– Direct flame + Cyclothermal + Convection

– Cyclothermal + Convection

Between a heating circuit and the next one, a protective shutter is placed in order to avoid air movements and temperature interferences.

HIGH TEMPERATURE

This special oven has been designed and realized for the products as like pizza, pita, piadina and similar that require high temperature and brief baking time.

Oven consist of assembled modular structure supported by steel frame fixed to the floor. As a consequence of the heating, the baking chambers have the possibility to dilate, thanks to a specially designed sliding system.

Chambers and the combustion groups are constructed from materials suitable for operation at high temperatures.

Thermal insulation of rock wool or ceramic fibers is enclosed by protection panels and stainless steel covers.

Heat transmission inside the oven is achieved thanks to the combustion generated by the radiant burners positioned on the top and the bottom of the baking chamber.

The heat transmitted to the product follows two principles:

– Irradiation: due to the temperature difference between the surface of the panel and the product;

– Convection: by the heated air that has been in contact with the flame.

Each baking zone is equipped with independent temperature control for both groups of burners positioned on the top side of the baking chamber and on the bottom.

Vapors and fumes created in the chamber, are extracted by a channel positioned longitudinally of the oven, connected to a chimney and equipped with suction fan and shutters.

Product transport is provided with stone conveyor chain.

Idle head includes a system of pneumatic tensioning.

Towing group, positioned on the output head, is composed of a motor controlled by inverter and a towing device that can be manually activated in case of emergency. Whole system is controlled by an electrical panel placed near the oven.